About HIPIMS Technology

HIPIMS (High Power Impulse Magnetron Sputtering) is a novel PVD technology for thin film deposition. It takes its origin on conventional magnetron sputtering but implements much higher power densities of 1-3 kW/cm2 , which is about 100 times higher than during traditional DC process. The power is provided in short pulses and small duty cycle in order to avoid overheating of the treated surface.

Multichannel HIPIMS technology takes the progress even further:

When working with short pulses of 5-15 µs, fast growth of the current maintain plasma density at the level of 1014 ions/cm3 and above. Since metallic atoms are sputtered from the cathode surface, they enter high density plasma and undergo effective ionization with high efficiency.

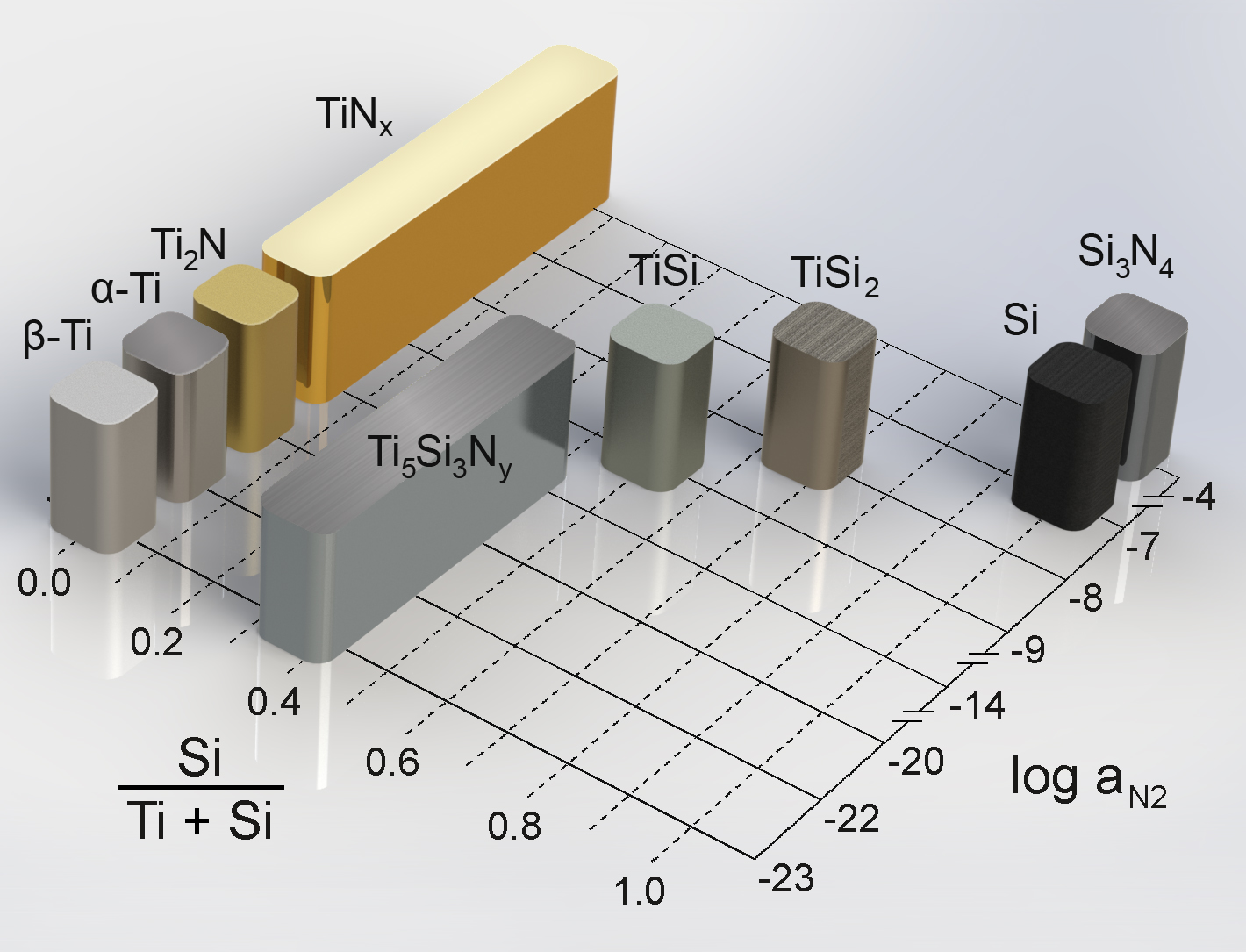

The figure demonstrates the range of thin film compositions when TiSi target is sputtered in nitrogen, which can be obtained by tuning processing parameters such as working gas pressure, discharge power, HIPIMS/substrate voltage, HIPIMS/substrate current, HIPIMS/substrate pulse length, frequency, number of pulses during the period, etc.

High density of metallic ions can be maintained for different materials, but typical are Ti, V, Nb, Zr, Ta, W, Cu, Al, C and their combinations in compound cathodes. Adding reactive components into working gas mixture increases the range of possible materials various oxides and nitride to complex compounds such as ceramics and MAX phases.

The benefits of Multichannel HIPIMS technology are difficult to overestimate. Accelerated ionic metals can be used for pre-treatment to increase film adhesion. During the deposition, the ions arrive at the substrate surface with energies much higher than in a conventional HIPIMS discharge.